I've started an Artist Residency at FACTUR

Posted on in Art Business

Tags: artist in residence, cnc, coworking, fablab, FACTUR, facturlabs, florida, hackerspace, laser cutting, laser etching, makerspace, orlando, residency, shopbot

It’s finally starting to feel like fall down here in Orlando – our version of fall, that is. I welcome the open windows and brisk mornings and evenings.

Last week I started a residency at FACTUR, “a member-driven fabrication laboratory and coworking space that serves as a creative home in which people work, learn and build a community rooted in science, art and technology. To that end, we endeavor to Learn. Create. Share.”

Sounds like a good fit for me, right?

Thanks to the generosity of the Lynn Brown Mautino artist scholarship, I have access to the space 24/7 for free for the next 6 months, PLUS $1000 for materials! There are all sorts of quality tools there – a laser cutter, a huge ShopBot CNC milling machine, 3d printers, lots of woodworking and metalworking supplies, and more. In addition to that, there are very knowledgeable members ready to share their expertise.

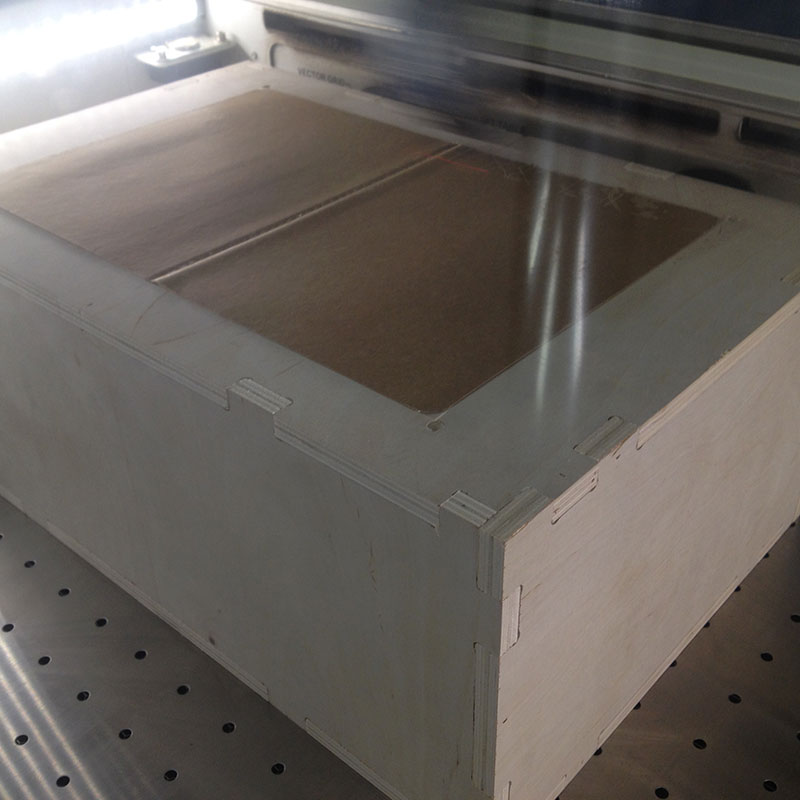

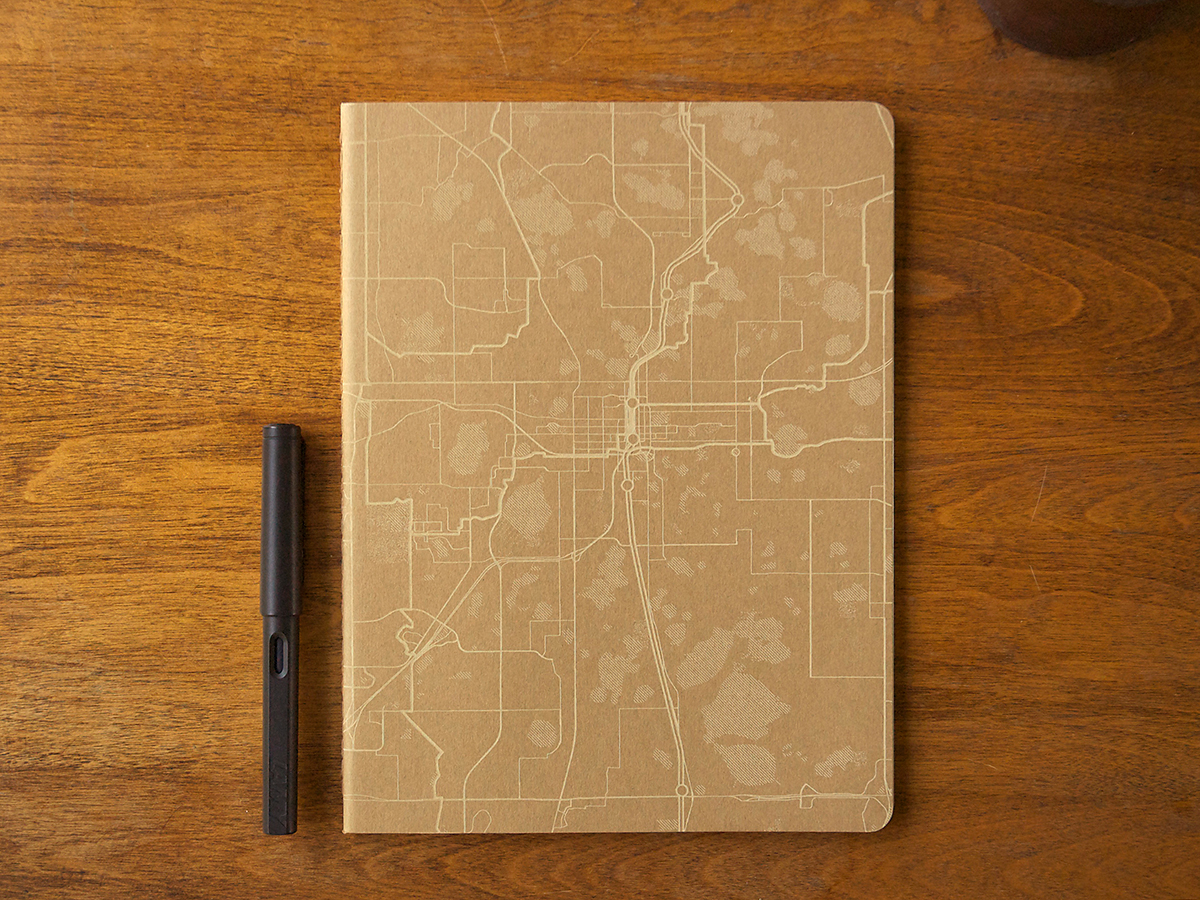

First on my list has been to refine the production of my Local Notebooks. In order to laser etch the front and back covers at the same time with consistent results, I had to create a custom jig to hold the notebooks. The first version of my jig that I made earlier this year worked pretty well, but had some issues that I wanted to address. So I made a new jig at FACTUR.

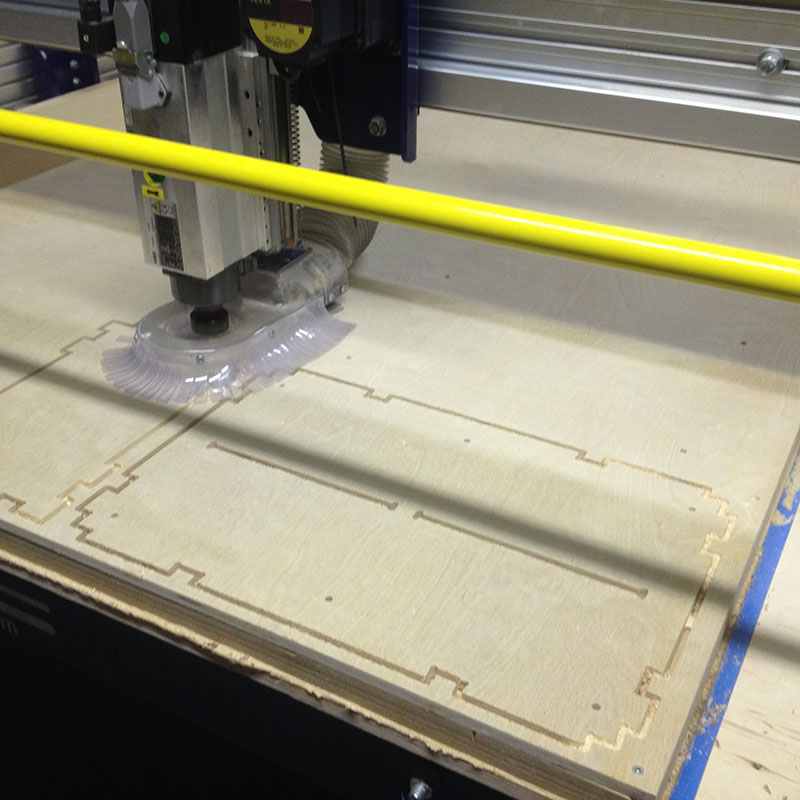

First I did some research and found a super useful web app that creates plans for a box that you can cut out with a laser cutter or CNC machine. You enter the outer dimensions of the box and the thickness of your material, and it spits out a PDF with properly spaced box joints. I tested it on a scrap piece of thin wood.

Then I attempted to create a bigger box with thicker wood (1/2″ ply), also on the laser cutter. There was some debate about whether the laser we have would be up for the challenge. Let’s just say it got through eventually, but left a charcoal-y mess.

Clearly not the right tool for the job 😉

So I modified my plan and worked with Tom Wynn, a master woodworker, to cut it out on the ShopBot.

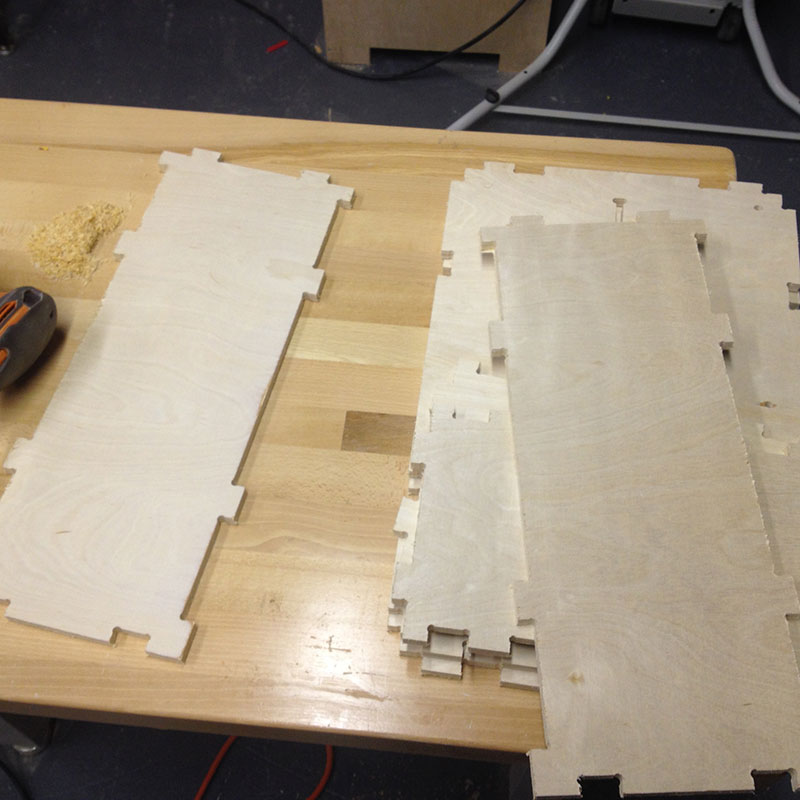

In the process of doing that I learned a lot about the machine, the software that we’re using to run it (VCarve Pro), and the finishing work that needs to be done once the raw pieces come off the CNC.

Eventually I ended up with my new small jig, which can etch one extra large notebook on one side, or two large notebooks on the other side. In the photo below left you can see how the notebook is open… the pages are hanging down through a slot in the box.

It’s working great so far and I already have the plans ready to make a large jig that can etch 5 extra large notebooks on one side or 9 large notebooks on the other side!

I’m having a great time making these notebooks. They’re quite affordable, and I would invite you to take a look at the different cities I have available. They make great gifts, and buying one is a really easy way to support me, and own something beautiful and useful that I’ve made! Thank you! Click here to see the designs.